The production process consists of the following processes:

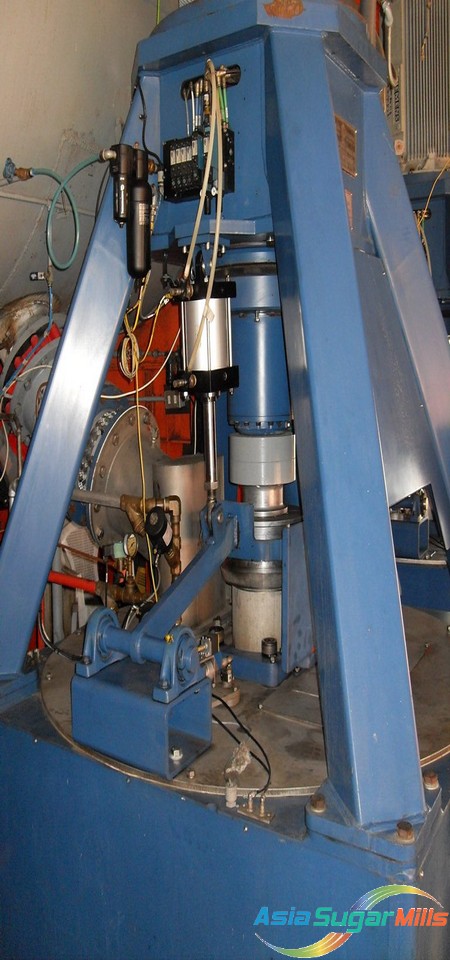

The rod is subjected to a process of preparation consists in breaking the cells of the stems. Then a conveyor belt leading to the mills, which performs the extraction of sucrose. bagasse leaves the last mill to chimneys, to use as fuel, bagasse or tank, where it is dispensed for use as material raw paper making.